opening work in process inventory formula

This formula can be used to calculate any of the four values given the other three are available. Therefore ideally Opening work in process - Closing work in process Units transferred - Equivalent units on which work is done.

Wip Inventory Definition Examples Of Work In Progress Inventory

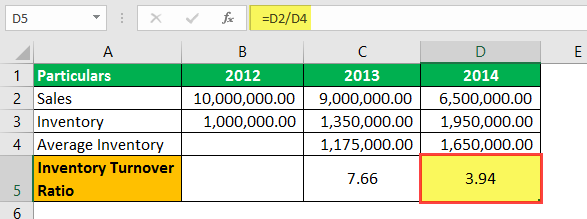

Work-in-process WIP inventory turns This asset management measure is typically calculated as the cost of goods sold COGS for the year divided by the average on-hand work-in-process material value ie.

. Formula for finding beginning inventory. A work in process or WIP for short is the term that refers to any inventory thats been initiated into production but hasnt been completed by the end of a companys accounting cycle. The work in process formula is.

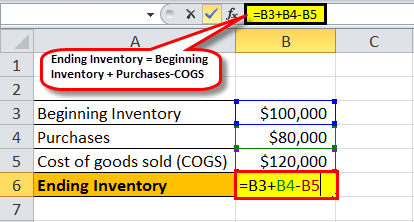

This results in a simple calculation to find opening inventory. Opening Inventory Cost of Goods Sold Ending Inventory Purchases. Lets use a best coffee roaster as an example.

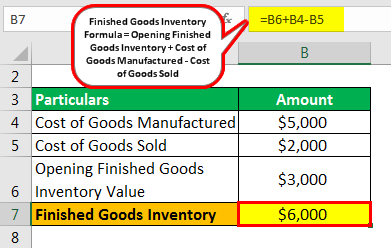

In this example the beginning work in process total for June is 50000 the manufacturing costs are 200000 and the cost of goods completed is 170000. Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs - Cost of Finished Goods. Opening amount costs of direct materials issued direct labor manufacturing overhead - costs of the manufactured goods.

Add the ending inventory and cost of goods sold. Additionally items that are considered work in progress may depreciate or face a lower demand from consumers once they have been completed. In this equation WIP e ending work in process.

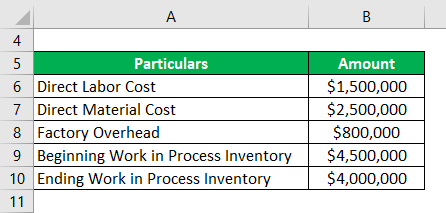

Cost of Goods Manufactured COGM Total Factory Cost Opening Work in Process Inventory - Ending Work in Process. Therefore many companies only calculate work in process inventory close to the end of a specific reporting period to minimize time spent on calculations. Next multiply your ending inventory balance with how much it costs to produce each item and do that same with the.

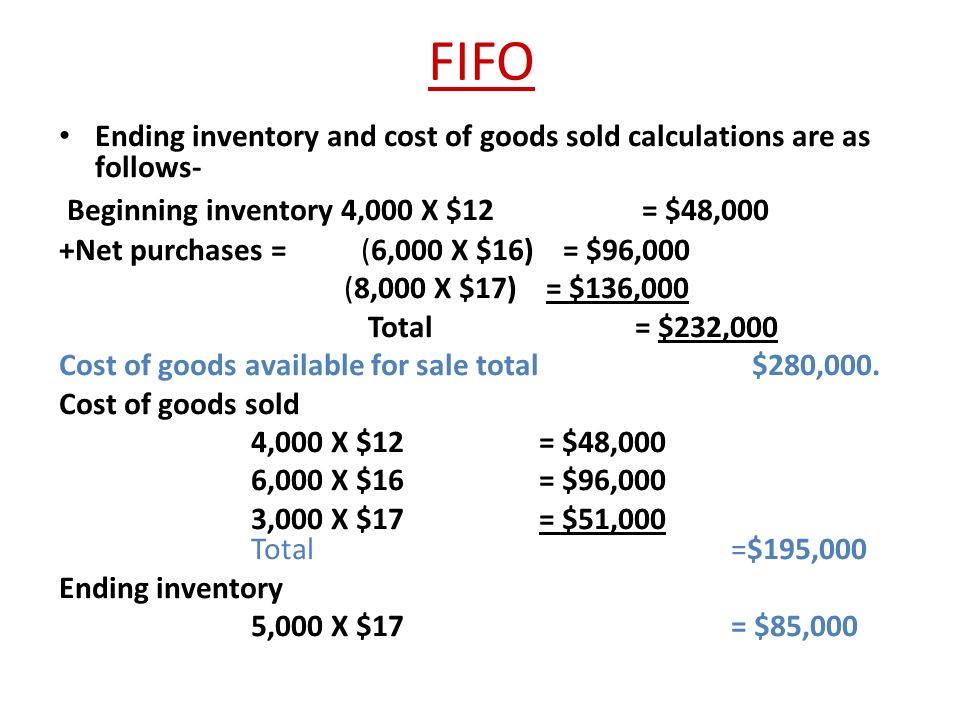

Work in process inventory formula. This beginning inventory equation or opening stock formula is. Accounting with Opening and Closing Work-in-Progress-FIFO Method.

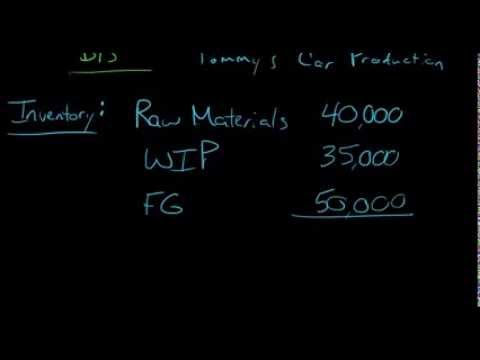

Its ending work in process is. Ending inventory 800 x 2 1600. Work in process operating inventory goods in process raw materials used during the period direct labor during the period factory overhead for a period ending inventory.

As adding all the cost incurred during the period to opening inventory of work in process. New inventory 1000 x 2 2000. How to Calculate Ending Work In Process Inventory.

Imagine BlueCart Coffee Co. Production in terms of. Opening Inventory Cost of Goods Sold Ending Inventory - Purchases.

ABC International has beginning WIP of 5000 incurs manufacturing costs of 29000 during the month and records 30000 for the cost of goods manufactured during the month. Has a beginning work in process inventory for the quarter of 10000. The initial work in process amount manufacturing expenses minus the cost of manufactured goods is the work in process formula.

Cost of Goods manufactured Direct materials cost Direct labor cost Factory overhead cost Opening work in process inventory - Ending work in process inventory. Determine the cost of goods sold COGS with the help of your previous accounting periods records. Add the ending inventory and cost of goods sold.

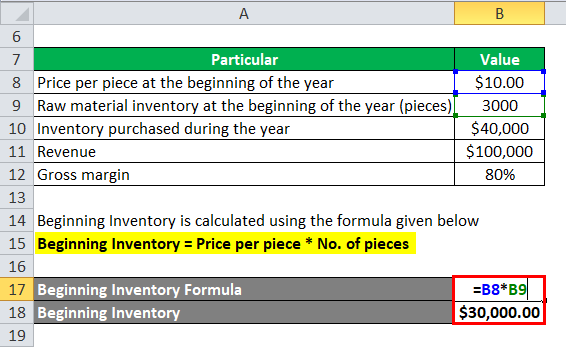

By simplifying the above formula we can say cost of goods manufactured is basically. Calculating work in process inventory is a complicated and time consuming process because it requires an assessment of the percentage of work completed and the cost associated with it. Beginning Inventory Formula COGS Ending Inventory Purchases.

Every dollar invested in unsold inventory represents risk. Let us take a company ABC which manufactures widgets. See the formula for calculating ending inventory above.

Ending inventory Beginning inventory Inventory purchases Cost of goods sold or Ending Inventory Beginning Inventory Inventory Purchases. 1600 1200 2800. WIP b beginning work in process.

Calculating your beginning inventory can be done in four easy steps. 2800 - 2000 800. Formulas to Calculate Work in Process.

Once youre able to determine your beginning WIP inventory and you calculate your manufacturing costs as well as your cost of manufactured goods you can easily determine how much WIP inventory you have. So when we calculate from the question. Opening Work in Process Equivalent units on which the work is done - Closing Work in process Units Transferred.

Opening Stock Formula Sales Gross Profit Cost of Goods Sold Cost Of Goods Sold The Cost of Goods Sold COGS is the cumulative total of direct costs incurred for the goods or services sold including direct expenses like raw material direct labour cost and other direct costs. This formula can be used to calculate any of the four values given the other three are available. 4000 Ending WIP.

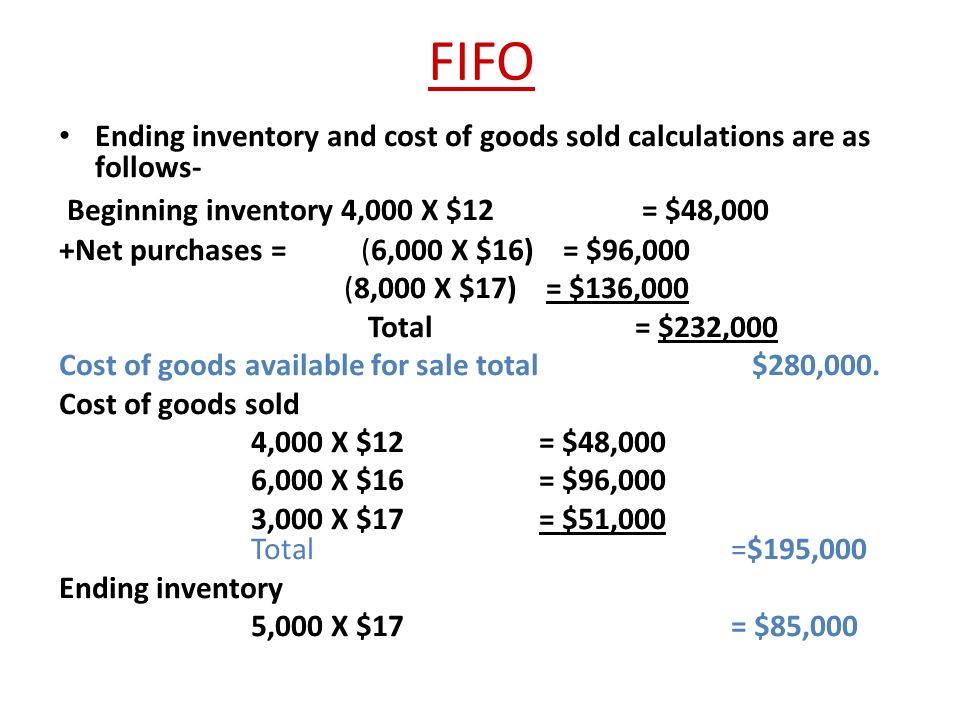

The formula for equivalent units units as follows. FIFO method assumes that those units which represent work-in-progress at the beginning are completed first and the units partly complete at the end of the period are units introduced or transferred from the preceding process during the current period. This product value is important for financial reporting.

However it excludes all the indirect expenses incurred by the company. And C c cost of goods completed. The work-in-process inventory that a company has started but not completed has specific value.

The value of all materials components and subassemblies representing partially completed production at plant cost for the most recently completed fiscal year. This beginning inventory equation or opening stock formula is. 5000 Beginning WIP 29000 Manufacturing costs - 30000 cost of goods manufactured.

Ending Inventory Sales - Inventory added to stock Beginning Inventory. Ending inventory Previous accounting period beginning inventory Net purchases for the month COGS. C m cost of manufacturing.

80000 70000 120000 125000 - 300000 95000. To calculate beginning inventory subtract the amount of inventory purchased from your result. Subtract the amount of inventory purchased from the number above to calculate the value of beginning inventory.

WORK IN PROCESS INITIAL WORK IN PROCESS DIRECT LABOR OVERHEAD - COST OF FINISHED GOODS. Total Manufacturing Costs Beginning WIP Inventory Ending WIP Inventory COGM.

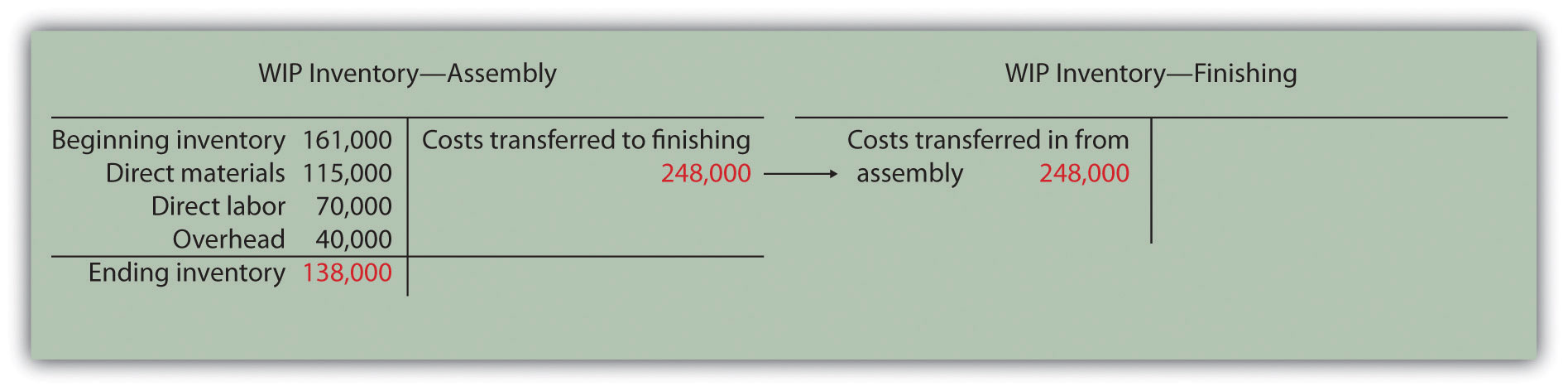

Compute The Cost Of A Job Using Job Order Costing Principles Of Accounting Volume 2 Managerial Accounting

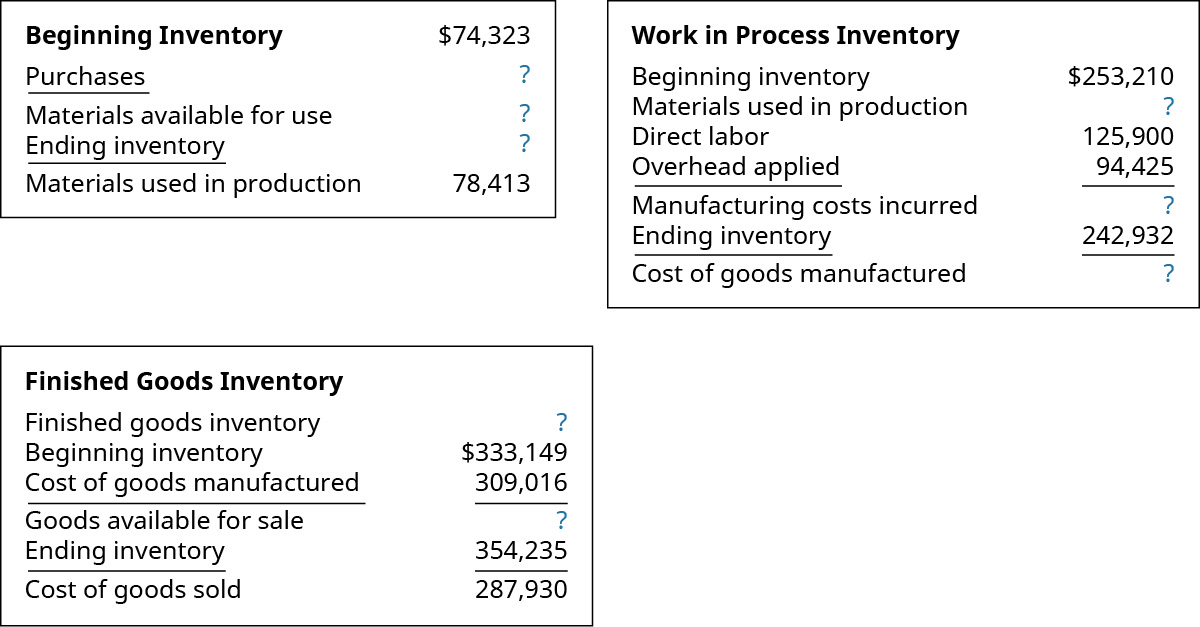

Cost Of Goods Manufactured Formula Examples With Excel Template

How To Calculate Ending Inventory Using Absorption Costing Online Accounting

Ending Work In Process Double Entry Bookkeeping

Cost Of Goods Manufactured Formula Examples With Excel Template

Inventory Formula Inventory Calculator Excel Template

Ending Inventory Formula Step By Step Calculation Examples

Ending Inventory Formula Calculator Excel Template

Finished Goods Inventory How To Calculate Finished Goods Inventory

Work In Process Wip Inventory Youtube

How To Calculate Finished Goods Inventory

What Is Inventory Turnover Inventory Turnover Formula In 3 Steps

Manufacturing Account Format Double Entry Bookkeeping

3 Types Of Inventory Raw Materials Wip And Finished Goods Youtube

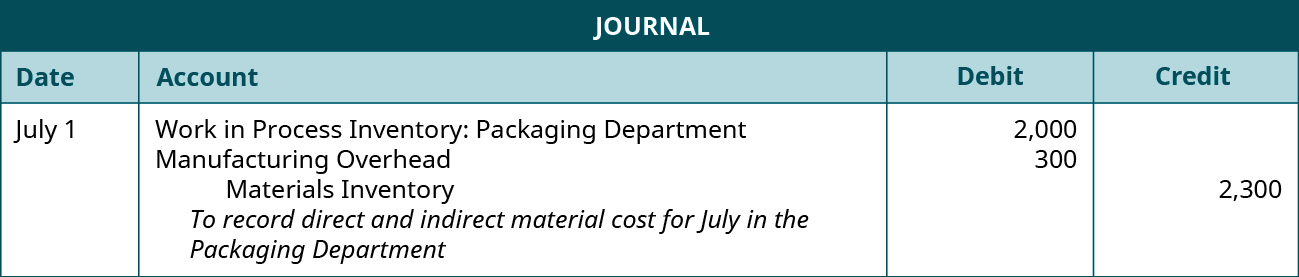

Prepare Journal Entries For A Process Costing System Principles Of Accounting Volume 2 Managerial Accounting

Finished Goods Inventory How To Calculate Finished Goods Inventory

How To Calculate Ending Inventory The Complete Guide Unleashed Software